DIESEL ENGINE BASICS

(This diesel engine guide is brought to you by Ian

McQueen)

A model diesel engine is a "compression ignition" engine,

physically the same as a glow two-stroke engine apart

from the design of the cylinder head, and we'll get

to that part later.

One of the facts of physics is that if a gas is compressed

quickly, its temperature rises. If the compression ratio

is high enough and the compression rapid enough that

very little heat is lost from the gas, the temperature

achieved is high enough to ignite an air-ether mixture.

This ether (di-ethyl ether, once used as an anaesthetic)

is a critical component of model diesel fuel because

of its low ignition temperature. Typically it makes

up 32% or more of the mixture.

The main power ingredient is kerosene (or jet fuel,

which is more highly refined). It has more energy per

unit volume than ether. The ether is required to ignite

it. The rest of the fuel is lubricant, usually castor

oil. It is much better if there is also 1.5 - 2% of

an ignition improver like the amyl/hexyl/octyl/iso-propyl

nitrate. This makes starting easier, makes the engine

run more smoothly, and reduces loads on internal parts

by reducing the compression ratio required to run the

engine.

Those are the fundamentals, but they don't begin to

explain the advantages of a diesel engine. I consider

the biggest feature of a diesel to be its great flexibility,

its ability to turn a large variety of propellers. Why

this is important leads first to a discussion of propellers.

Propellers

A given engine can drive a propeller of large diameter

and low pitch or one of small diameter and high pitch.

A large-diameter, low-pitch prop moves a large volume

of air at moderate speed and provides high thrust.

It is like low gear in a car: lots of pulling power,

but not able to move the vehicle very fast. And a small-diameter

prop turning at high speed provides a high-speed blast

of a relatively small volume of air. It is like high

gear: it doesn't have the thrust to get the car moving

from a standstill, but can drive it to high speed once

the car is moving.

On a racing plane, a large, low-pitch prop would scarcely

get the model flying. On a slow-flying model, a small

prop turning at very high speed would generate very

little thrust and would have difficulty getting the

model moving.

For a slow-flying model, the optimum large prop will

be turning at a relatively leisurely pace, say 6,000

- 11,000 rpm, while the smaller prop of a fast model

will be going a zillion rpm. Converted from metric,

a zillion might be 11,000 up to more than 30,000 for

racing. In any case, the pitch must be high enough to

move the plane at the intended speed when it is turning

at the speed that the engine is able to turn it.

Glow engines are usually designed to develop their

power at quite high rpm, say 11,000 to 15,000 rpm or

more. They are happiest with relatively low loads, in

the form of props with relatively small diameters. If

loaded down with a large prop, they may overheat due

to pre-ignition. Here's a brief description of why.

In a glow engine, the fuel will begin to burn at a

fixed point on the upstroke (with some caveats). With

a suitable, relatively small, propeller, this point

will be such that the engine fires at just the right

time so that the maximum pressure is reached just at

TDC.

If you put a large prop on that engine, it will still

fire at exactly the same point on the upstroke. However,

the higher drag of the prop is causing the crankshaft

to turn more slowly and prevents the piston from moving

as quickly. The result is that maximum pressure will

be reached before the piston reaches TDC.

This is pre-ignition and puts a strain on all moving

parts of the engine: the piston crown, piston pin, con

rod, and crankpin. It can often be heard as a pinging

or cackling, and the effect is that the engine will

overheat. It can be seriously damaged. (Note that the

fuel in a properly-operating engine "burns" very rapidly,

but it is still burning. It does not "explode" or "detonate".

Those words describe undesirable pre-ignition.)

A diesel, on the other hand, can turn the ordinary

props used on glow engines at very respectable speeds,

but it can also swing larger props because the ignition

timing can be varied so that the fuel begins burning

at just the right point on the upstroke, just as the

spark is timed precisely in an automotive engine. How

is this done?

A model diesel has a screw of some kind in the head.

(There are a few exceptions, but they're not important.)

It pushes against a contra-piston, a movable "plug"

inside the top of the cylinder that forms the top of

the combustion chamber. Pushing the contra-piston down

with the screw decreases the volume and thus increases

the CR, so the point on the piston upstroke where the

required temperature is produced is lowered. This advances

the timing.

Conversely, turning the screw out allows the contra-piston

to be pushed farther up the cylinder when the piston

rises and the trapped gas presses against the bottom

of the contra-piston. (Sometimes it sticks, but that's

one of the things that make diesels so interesting!)

Raising the contra-piston lowers the CR and retards

the timing so that a larger prop can be driven with

no risk to the engine.

To show the effectiveness of this control, the people

at PAW once put a huge 18-6 prop on a PAW 35 engine

and started it. It could turn only 3500 rpm, but it

ran for five hours straight with no damage to the engine!

The test was stopped just because the people wanted

to go home.

To vary the ignition point of a glow engine it is necessary

to try different glow plugs, install or remove head

shims to reduce or raise the compression ratio (in effect,

a glow-engine is a glow-assisted diesel!), and play

around with the percentage of nitromethane in the fuel.

Compare this with merely turning the compression-adjusting

screw of the diesel engine.

Other advantages:

In addition to the greater flexibility of a diesel

engine vis- -vis glow, a diesel offers the following

other advantages:

- lower noise level

- more pleasing, more "masculine" sound quality

- longer running time on the same volume of fuel

- no need to buy glow plugs or batteries

- a certain aroma that is guaranteed to identify the

modeller as a real "diesel man"

STARTING AND ADJUSTING FUEL

The fuel consists of kerosene for power, ether to ignite

the kerosene, lubricant, and an ignition improver. Here

are some notes about the ingredients.

Lubricant

There have been many fuel formulas, with oil content

ranging from 12% (for racing in ABC engines) to 33%

(old "British" formula). Recently I saw up to 40% for

breaking in the MP Jet engine, but that seems really

high!

In the typical diesel, with an iron (Meehanite) piston

and hardened steel cylinder, the minimum oil content

recommended is 23%. It's a characteristic for proper

lubrication of those two materials. A safe bet is 25%

oil for any engine. That way there's lots of lubrication

for the connecting rod. PAW recommends 30% for break-in,

and it isn't going to do any harm to run higher oil

(over 25%) all the time, but the surplus is going to

go out the exhaust and may not contribute much to lubrication

beyond 25%.

"Oil" is taken to mean castor oil, the best lubricant

for model engines.?

There is greater force on the con rod bearings of a

diesel than of a glow engine, so the insurance of the

castor oil is well worth the added mess from the exhaust

spray.

Ether

Typical ether content is 32%. This assures good atomization,

and also gives a safety margin for loss due to evaporation,

for the ether will evaporate quickly if the container

is left unsealed (especially when the air is hot).

Engines will run on lower percentages; apparently 25%

is no problem, and probably one can go lower yet. But

at some point the fuel will not atomize as finely and

power can be expected to drop. There might also be some

effect on combustion, and possibly it would be necessary

to increase the compression to get the fuel to ignite

early enough on the upstroke. This is not a good idea,

for it will impose heavier loads on the moving parts.

Some fuels are even higher than 32% in ether. They

will burn cooler than "standard" fuel and will produce

less power, but there may be some times when this is

an advantage, as with a Cox International head for a

Cox engine; the lower temperature is not as likely to

melt the Teflon disc that seals the top of the cylinder.

This disc melts when "normal" fuel is used and the

engine is tuned for full power. It is my understanding

that fuel for the Cox International-converted Cox engines

should have about 40% ether. Higher ether content can

apparently be used if an ignition improver chemical

is not available, but I have no real information on

this.

Ether used to be easy to obtain when it was still being

used as an anaesthetic. But it is not used for that

purpose any more, so there is little incentive for drug

stores to carry it. And ether is also used in processing

some illegal drugs, which has made it difficult for

legitimate users to obtain it.

Starting spray for full-size engines contains ether.

One source is John Deere dealers. One freezes the container

and punctures it to release the ether, but I have never

done this, and these instructions are not enough to

teach you how to do it safely!

Ignition improver

The ignition improver, like Ethyl's DII(3) (octyl nitrate),

causes the ether to ignite at a lower compression ratio,

and also smoothes the combustion process. Without it,

a diesel has a cackly, rattly sound, and compression

has to be set higher, which puts more load on the moving

parts.

With it, a diesel runs smoothly and purrs like a tiger.

A typical formulation is 2% for engines up to about

.19 and 1.5% for larger engines.?

Kerosene

Kerosene or jet fuel makes up the balance. Kerosene

has higher energy per volume than ether, so a higher

percentage of kerosene is desirable. But this is limited

by considerations of ignition and lubrication.

Commercial fuel

The simplest way for most modellers to obtain diesel

fuel is to obtain it from one of the commercial manufacturers/suppliers.

Companies that I know of that sell diesel fuel in the

USA are:

- Aerodyne

- Red Max

- Ed Carlson

OPERATION

The following instructions begin with starting a diesel

engine, then branch to adjusting it for full power output

(for a broken-in engine) and for break-in (for a new

engine).

STARTING THE ENGINE

Probably the most difficult part of running a diesel

engine is getting it to fire the first time.

This may not seem like a particularly profound statement,

but they do have to be set within a small range of adjustments

to fire properly. One would think that it is only necessary

to crank the compression high and it should fire. But

it doesn't work that way. The engine can be just as

reluctant to start if the compression is too high as

it is if the compression is too low, maybe even more

so.

The following method of starting a diesel is my own,

which I immodestly call the "McQueen Method" since I

have never seen the key part described anywhere else.

The key part? Whereas other starting instructions always

seem to include the words "Fill the tank" at the beginning,

I emphatically say "Do not fill the tank!!" Determine

the correct starting settings by running the engine

only on a prime. Then fill the tank, get the engine

to run continuously, and adjust it for full power.?

Why this way?

The reason is because a diesel is easy to flood, and

a flooded diesel is very difficult to start. The idea

is to put a controlled amount of fuel into the engine

and to start the engine on that. But if there is fuel

in the tank, it is very likely to dribble into the engine

and interfere with your efforts to put in that right

amount of fuel.

Note that there are ways around the problem of flooding

if it occurs, and I'll include them below, but they

require a lot of unscientific fiddling and tomfoolery

that can be avoided if you follow these instructions

carefully and understand why you are doing what you

are doing. (Much of the information here can be usefully

adopted for starting glow engines.).

The most important single instruction is: DO NOT FLOOD

THE ENGINE!

PREPARATIONS

Mounting the engine

Mount the engine on a strong mount (or in a model).

It is convenient if the engine can be removed from a

mount without too much difficulty in case it is necessary

to invert it and drain out excess fuel, though this

will not be a problem if you are careful and don't flood

it. And excess fuel can be cleared if you just flip

the prop long enough. (Reduce the compression initially

to reduce load on the innards.) Do not mount the engine

inverted.

Fuel system

The fuel tank should be positioned as with any model

engine, as close as possible to the engine and with

the center line of the tank no higher than the spraybar.

(Some sources say to put the top of the tank level with

the spraybar. Partly this depends on the ability of

the engine to draw fuel.)

And, as touched on above, keep the spraybar higher

than the tank (or the supply line pinched off) when

the engine is not running, to keep fuel from dribbling

into the engine.

For flexible fuel line, use only neoprene. Silicone

tubing should not be used because it swells up in contact

with diesel fuel, though you should get by using it

for a day if you are prepared to replace the tubing.

Ordinary PVC (vinyl) tubing can be used where flexibility

is not needed. It will become stiff after prolonged

contact with fuel.

Propeller

Select a prop of suitable size from the engine manufacturer's

instructions. For break-in, a "suitable size" is one

of greater length and lower pitch within the mid-range

of sizes suggested in the instructions (so that it will

not place a heavy load on the engine). And, the heavier

the prop - such as nylon, the better for greater flywheel

action. Mount the prop so that the piston comes up against

compression at the "ten past eight" position

Compression setting

The screw in the head, and thus the position of the

contra-piston, are usually in the right ballpark when

the manufacturer packages the engine. You did resist

the temptation to turn that little screw, didn't you?

PAW test runs every engine to make sure that it will

start. Other manufacturers might, also. If it has been

moved from the initial position, try to remember where

the screw was and return it to that position.

Grasp the prop and try turning the engine over. The

engine should turn over freely, though compression should

be good. If it feels difficult to turn over TDC, compression

may be too high. Back the compression screw out at least

a quarter turn (it can be more if "little fingers" have

been playing with the comp screw) and flip the prop.

This should push the contra-piston up, and the resistance

due to compression should be reduced.

If the engine turns over freely, it should be in the

ballpark. If the engine turns over very easily, it is

possible that the compression has been set too low.

It is just as well to do nothing at this point, but

keep in mind that it may be necessary to increase the

compression later.

As noted earlier, starting is not easier when compression

is too high. It seems to make the engine actually harder

to start. Often the engine may be under-compressed but

a really hard flip will get it to fire anyway. It won't

run properly, but it will still show some life. These

uncertainties are what make diesels so much fun!

Throttle setting

Set the carb wide open.

Priming

Obtain a small squeeze bottle that you can fill with

fuel and then use to measure out fuel drop-by-drop.

This ability to measure drops accurately is very important

to avoid flooding.

I always prime an engine through the venturi or carburetor,

not into the cylinder. Some modellers are successful

with prime against the side of the raised piston. But

if there's a muffler this becomes impossible anyway.

Note that putting even a small amount of fuel into

the cylinder decreases the volume, thereby raising the

compression ratio. If the CR is just right with the

prime, what happens when the fuel burns? The volume

decreases, so does the CR, and the engine will likely

stop. Or, if the CR is just right for running, the extra

volume of fuel may be enough to raise the CR beyond

the point where the engine will fire.

A prime into the intake allows the fuel to be vaporized

and carried into the cylinder in the same way as when

the engine is running normally. A correct prime is literally

only a couple of drops. Literally!

For small engines, .06 and smaller, it should be a

single drop, or even a partial drop into the venturi.

(Make a drip on the end of the tube and then touch it

to the venturi to make it drop into the intake.) For

one over, say, .19, it could be two drops and maybe

three for a big engine.

But don't go over two drops at first. That should be

enough to get the engine to fire and run briefly.

Putting the right, small, amount of fuel into the engine

is the single most important part of getting your engine

running!

STARTING THE ENGINE

Prime the engine as just described. Hold the prop in

your hand and turn the engine over slowly. This is to

ensure that the engine is turning freely and that the

dreaded hydraulic lock has not occurred.

Bring the prop up against compression and then flip

it as hard and as quickly as you can. A sharp snap is

the key to good starting.

If you are really lucky, the engine will start and

run for about a second with a good burst of power. This

is the optimum response and your target with this exercise.

My engines usually do not fire until the second or

third flip, so don't be discouraged if you are not successful

on the first flip. Repeat the hard flip, several times

if necessary. The following responses are possible:

- If the engine starts with a good burst of power,

perfect. The compression setting is good.

- If the engine starts, but runs weakly with a "soft"

sound and/or misfires (skipping), and soon dies, it

is under-compressed. Turn the comp screw in a small

amount, about 1/16 of a turn, and flip again a few

times without re-priming in case there is still fuel

left in the crankcase. If the engine does not fire,

prime and try again.

- Repeat these steps as necessary until there is that

good burst of power, and then repeat once to make

sure that the action is repeatable. (A slight complication

is that running the engine several times will warm

it up a little, and that has the same effect as increasing

the CR a small amount.)

- If the engine starts, but runs with a harsh, metallic,

rattly, or clattery sound, and stops abruptly, it

is over-compressed. Turn the comp screw out 1/8 -

1/4 turn and flip again a few times to push up the

contra-piston and to clear out any fuel. It may start

while you are doing this. If not, re-prime and try

again.

Repeat these actions until the engine fires and runs

reliably with a good burst of power; then proceed to

"RUNNING AND ADJUSTING THE ENGINE".

Flooding

If the engine does not start after several tries of

these instructions, it may be flooded. Full instructions

for clearing a flooded engine are given at the end.

Clearing a flooded engine is a general pain, and the

fiddling necessary to clear it can get aggravating.

Try to avoid flooding it.

RUNNING AND ADJUSTING THE ENGINE

At this point the engine has run out the prime with

a good burst of power. Make a note of the position of

the comp screw. (I make a scratch on the head to match

a mark or feature on the screw.) That position is your

starting point (unavoidable pun) in future for a prop

of that size.

In colder weather, you may have to turn the screw in

slightly from that point; likewise, if you later fit

a prop of less diameter and/or pitch (reduced load).

And you may have to back the screw out slightly in hot

weather or if you fit a prop of larger diameter and/or

pitch (increased load).

At this point you are ready to run the engine.

Needle valve and throttle positions

Needle valve: The instructions with the engine should

give an indication of a suitable starting position for

the needle valve. For an unfamiliar engine being run

for the first time, especially for break-in, I usually

open the needle valve three to five turns from fully

closed.

An alternative method used by diesel expert David Larkin

is to start with the needle valve open only about half

a turn and to open it a quarter turn with each unsuccessful

attempt to keep the engine running, but the engine might

then run at quite high speed when it catches, and this

can be undesirable for an un-run engine.)

Throttle: The throttle should be wide open. (With experience

you can start at reduced settings; for engines converted

from glow with a Cox International head, set the throttle

about half-open.)

Filling the tank

Fill the tank. Be sure that your fuel is fresh. If

too much ether has evaporated from the fuel, you will

be wasting your time!

While filling the tank, clamp off or disconnect the

fuel line to the engine so that no fuel can leak into

the engine. And, when starting the engine, either pinch

off the fuel line with a finger or hold the nose of

the model high (if it's a small-enough model) so that

gravity will keep fuel from leaking into the engine.

When the engine fires, release the line or return the

nose to horizontal. The engine should run long enough

on the prime to draw in fuel and keep running.

Usually there is no need to draw fuel up to the spraybar

beforehand. Fuel will usually be drawn to the engine

when it starts.

Starting the engine

With the fuel line pinched against the engine or model

with a finger (or the nose held high), prime the engine

and flip it the same way that you did successfully above.

As soon as the engine fires, remove your finger from

the fuel line (or bring the nose to or below the horizontal).

Fuel will usually be drawn to the engine and the engine

will keep running. If the engine doesn't keep running,

immediately clamp the fuel line (or lift the nose),

open the needle valve 1/4 to 1/2 turn and repeat.

When you get the engine to keep running, congratulations!

You are well on the way now!

And if you are using the method of opening the needle

valve in steps from closed and if the engine doesn't

keep running after the prop has been flipped several

times, immediately clamp the fuel line (or lift the

nose), open the needle valve 1/4 to 1/2 turn, prime,

and flip again. Repeat as necessary.

Adjusting the engine

At this point the engine is running and needs to be

adjusted. Instructions are given first for starting

and setting an engine that has already been broken in.

Instructions for a new engine are given later.

The compression screw and needle valve settings interact

with each other. The main adjustment is the compression

screw. But when the CR has been set properly, the next

step may be to lean the fuel mixture more.

That will make the engine run hotter, which advances

the ignition point, and that in turn may require reducing

the CR to retard timing slightly. The following should

enable you to adjust the right one at the right time

and get the engine adjusted correctly. This may seem

daunting the first time, but it becomes instinctive

quickly when you understand why you are making an adjustment.

I'd like to be able to post a flowchart at this point,

for it simplifies the rest of the instructions. But

I can't, so just follow the words.

Let the engine run for half a minute to warm up, then

go through the following questions and actions.

Is it running softly, misfiring, skipping, loping,

etc? If so, CR is too low. Turn the comp screw in 1/8

turn.?

Alternatively: Is it running harshly, sounding laboured,

rattly, cackly? If so, turn the comp screw out 1/8 turn.

Repeat these evaluations and adjustments until the

engine is running smoothly then continue to adjusting

the needle valve.

Note: We got to this point by gradually adjusting the

needle valve until the engine would keep running, so

it should be in the ballpark of the correct setting.

Is the engine exhaust very oily? Is the engine four-stroking?

If so, it is running too rich. Close the needle valve

1/8 to 1/4 turn, allow a few seconds for the change

to take effect, and check again. Repeat this check until

the engine is "singing" at a good speed.

When the engine is tuned for nearly full power, it

will heat up and this advances the ignition. Has the

engine sound become laboured, harsh, rattly, or cackly?

If so, reduce the CR 1/8 to 1/4 turn and check the sound

again.

Continue to close the needle valve in small steps.

If the engine speeds up, you are going in the right

direction. Repeat the procedure. If it begins to misfire,

it is probably too lean. Open the needle valve enough

to restore smooth operation.

If misfiring occurs, the compression may be set too

low. Turn the comp screw in 1/8 to 1/4 turn. If the

engine speeds up, you are going in the right direction.

If the engine sound becomes laboured and harsh, back

the comp screw out to the former setting or even beyond.

This procedure will have you close to the full power

output. If the engine is in a model, try flying it.

NOTES:

Once the model is released and it accelerates, it is

possible that the engine will start to misfire, especially

if the engine is fitted with a large, high-load prop.

Do not try to fly if it is misfiring. It may not be

developing enough power.

The needle valve may be too lean, and probably the

CR is a little bit too low. (As the plane moves forward,

the load on the prop is reduced and the engine can turn

faster, needing more fuel. And the ignition point may

need to be advanced a little.) Turn the comp screw in

about 1/16 turn and open the needle valve a little.

Try again. Repeat the adjustments as required.

In general it will probably be necessary to richen

the mixture slightly and increase the compression slightly

from the initial settings to develop maximum power in

the air.

Miscellaneous notes

You do not have to worry about a lean setting damaging

a diesel the way it would a glow engine. If a diesel

is set too lean it will misfire or simply stop.

Once you have become familiar with your engine, particularly

if it is .19 or larger, you may be able to prime the

engine by choking the inlet and turning the prop enough

to draw fuel to the inlet. But this can be tricky, for

there is the risk of flooding, especially for small

engines.

Diesels run cool and the exhaust is much cooler than

glow-engine exhaust.

You can put a piece of ordinary PVC tubing on the outlet

of the muffler to guide exhaust away from the model.

The tubing can be up to a foot (30 cm) long without

detriment to engine operation.

Except when the engine is running very rich, the exhaust

has a color. With a light load, the exhaust will be

a light tan. But the more heavily it is loaded with

a large prop, the more the exhaust will tend toward

black. Hence the usefulness of the tubing to keep exhaust

oil off the model. (Minimize the amount of this exhaust

that gets onto your clothes, for it has a distinctive

aroma that not everyone appreciates! Especially wives.)

BREAK-IN

The instructions with your engine will probably cover

this, but here are a few tips anyway.

Iron-steel engine: The procedure is to run the engine

for a couple of minutes, stop it and let it cool, then

run it again. The engine is initially run in a very

rich four-stroke, with just enough compression to keep

it running smoothly.

I build up about 20 minutes at the richest setting,

then close the needle valve 1/4 turn for each successive

run until the engine is beginning to break into two-stroking.

I give it short bursts of moderate-speed two-stroking,

again with just enough compression for smooth running,

followed by richening it again to keep the engine from

running hot too soon. This two-stroking is gradually

increased in duration and maximum speed.

When the engine (any engine) is manufactured, the surfaces

of the piston and cylinder are like microscopic mountains

facing each other. The slow break-in allows removing

the tips of the peaks an atom or two at a time instead

of gouging out chunks of metal. The finished product

is a pair of smoothly polished surfaces to run against

each other. The reason for slow running and not letting

the engine run hot at first is to prevent metal expansion

that would push the peaks into hard contact with each

other so they break.

ABC engine: The procedure is completely different for

ABC engines. The principle here is to get the engine

reasonably hot as quickly as possible, for the fit between

cylinder and piston is usually very tight at TDC and

one wants to expand the top of the cylinder enough to

provide the normal running clearance. One should use

a relatively small propeller so the engine can turn

freely and quickly find optimal CR and needle valve

settings to run relatively rich at high speed.

(K&B, in their instructions for breaking in a glow

6.5RIRE ABC pylon engine recommended a prop cut down

so the engine would four-stroke at.....20,000 rpm! Use

this information for guidance.)

TROUBLESHOOTING

Clearing flooding

You will flood an engine at some time. Here are some

tips on clearing it. They are based on an engine in

a model so it can be inverted easily. If the engine

is in a test stand, there are ways to clear flooding,

but removing the engine for draining remains an option.

Block the fuel line. Invert the engine and drain fuel

out of the intake and the exhaust. Rock the prop back

and forth several times to ensure that the ports open.

Turn the engine upright, back off the comp screw 1/2

to 1 full turn. Hold the prop with your hand and turn

it over against compression. If it turns easily, continue.

However, if there is resistance, keep backing off the

screw until it will turn freely.

Begin flipping the prop.

The engine may start at some time. This will either

clear out all the fuel and the engine will run and then

come to a soft stop. Or it could draw up a slug of liquid

fuel if the engine was really badly flooded. In this

case the engine could stop abruptly. If this happens,

drain out any fuel possible, reduce the compression

more, and flip again.

Eventually the excess fuel will be cleared out, compression

will again feel soft, and you will need to increase

the compression a little at a time. When the engine

is somewhere around the normal starting setting, follow

the starting procedure from the beginning.

This business of clearing a flooded engine is a general

pain, and the fiddling necessary to clear it can get

aggravating. If you are careful not to flood the engine

you should be able to avoid this monkey-foolery completely.

But some time your engine is going to get flooded and

you have to know how to clear the problem.

Poor compression

The engine must have good compression if it is to start

easily. There are ways around poor compression, and

I have had to use them with several engines converted

to diesel operation. This is not a reflection on the

heads, but on the engines.

My problems came with one O.S. 25FSR and all three

of my 10FSR engines. All of the 10FSRs had poor compression

from new, as did a replacement piston-sleeve set that

I put into a 25 engine worn by fine dust at our flying

field. I don't know if O.S. was making them so loose

that users could not seize them up with lean runs as

glow engines, but the 10s were so loose that they were

very difficult to start even as glow engines.

If your engine has poor compression, it is better to

repair it (new internal parts). However, there are ways

around the problem.

If you have an electric starter, you can try using

it, but very carefully. If the CR is too high, or if

hydraulic lock occurs, you can quickly bend a con rod.

Be sure that the CR is a little on the low side, and

be sure that there is no fuel in the engine (not flooded).

Set the throttle to the maximum and the needle valve

out enough turns for running.

Then apply the starter to the prop, as lightly as possible

so the rubber cone can slip if the engine resists turning

over.

If the engine does not turn over easily, stop immediately

and reduce the CR. Also check for excessive fuel inside

the engine. I could always start the 10FSRs quickly

with a starter.

If you don't have a starter, set the CR and needle

valve to approximately the running settings. But this

time you have to get just enough liquid fuel into the

crankcase that you can invert the engine and have liquid

drain around the piston and seal it. Then turn it right-side-up

and immediately begin flipping. (Don't use a starter

this time!) With luck the fuel will give enough compression

seal to get it going.

Sometimes I have had to do the flipping inverted and

then right the model when the engine fired, but this

was with small models that I could hold in one hand.

If you have a new engine you should never need to use

these emergency methods.

|

![]()

You will need:

You will need:

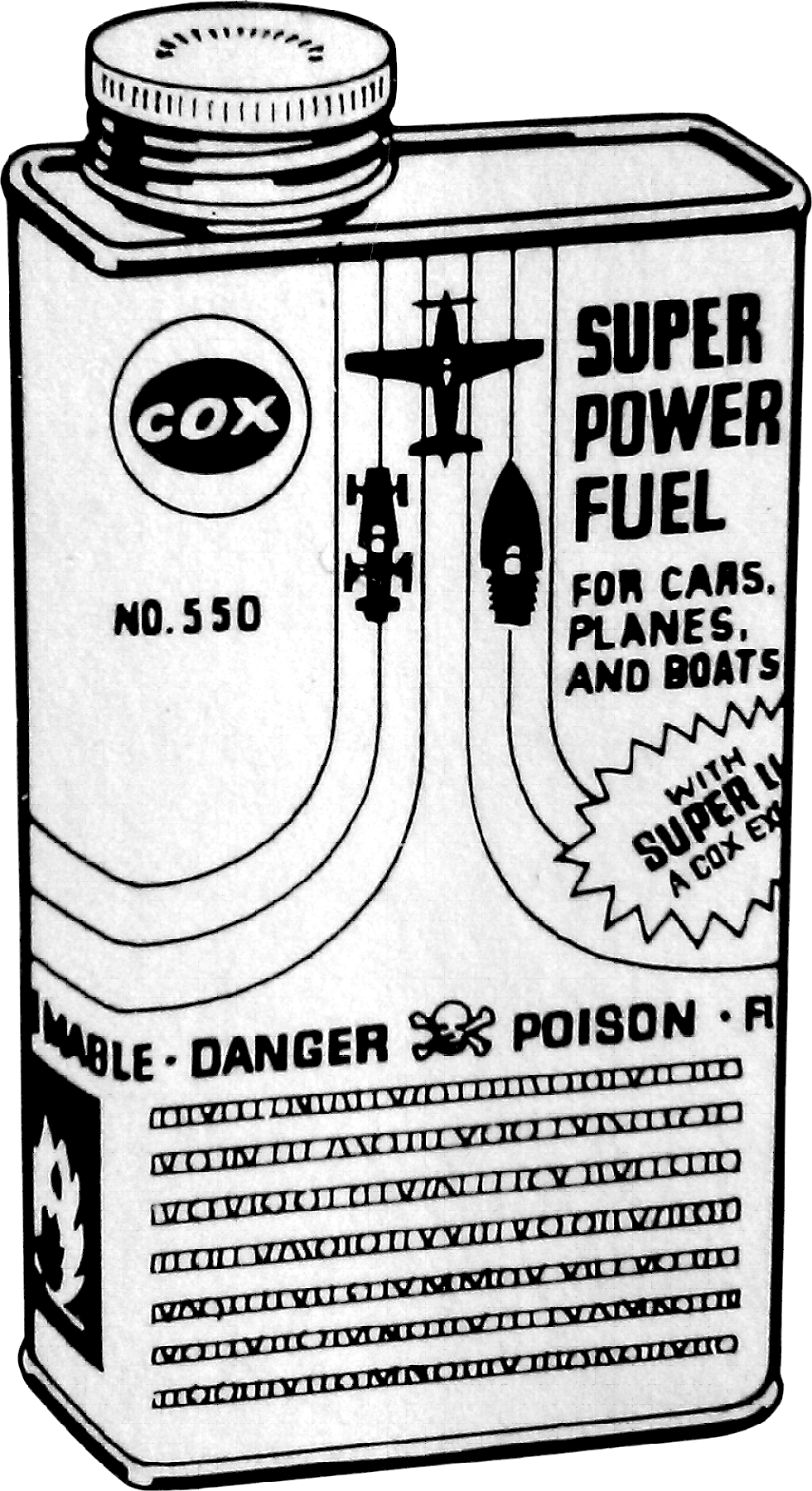

Cox

engines typically run on what is termed " A fuel", a fuel

with high nitro content and containing some castor oil

instead of synthetic oil only. This fuel mixture is

becoming increasingly difficult to obtain. Often, when referring

to " A" in hobby shops, it will elicit blank stares. A

fuel in loose terms is 15-35% nitro (a.k.a. nitromethane),

20% (castor) oil and the balance methanol (a.k.a. methyl

alcohol, carbinol, wood alcohol, wood naphtha or wood spirits).

Cox

engines typically run on what is termed " A fuel", a fuel

with high nitro content and containing some castor oil

instead of synthetic oil only. This fuel mixture is

becoming increasingly difficult to obtain. Often, when referring

to " A" in hobby shops, it will elicit blank stares. A

fuel in loose terms is 15-35% nitro (a.k.a. nitromethane),

20% (castor) oil and the balance methanol (a.k.a. methyl

alcohol, carbinol, wood alcohol, wood naphtha or wood spirits).