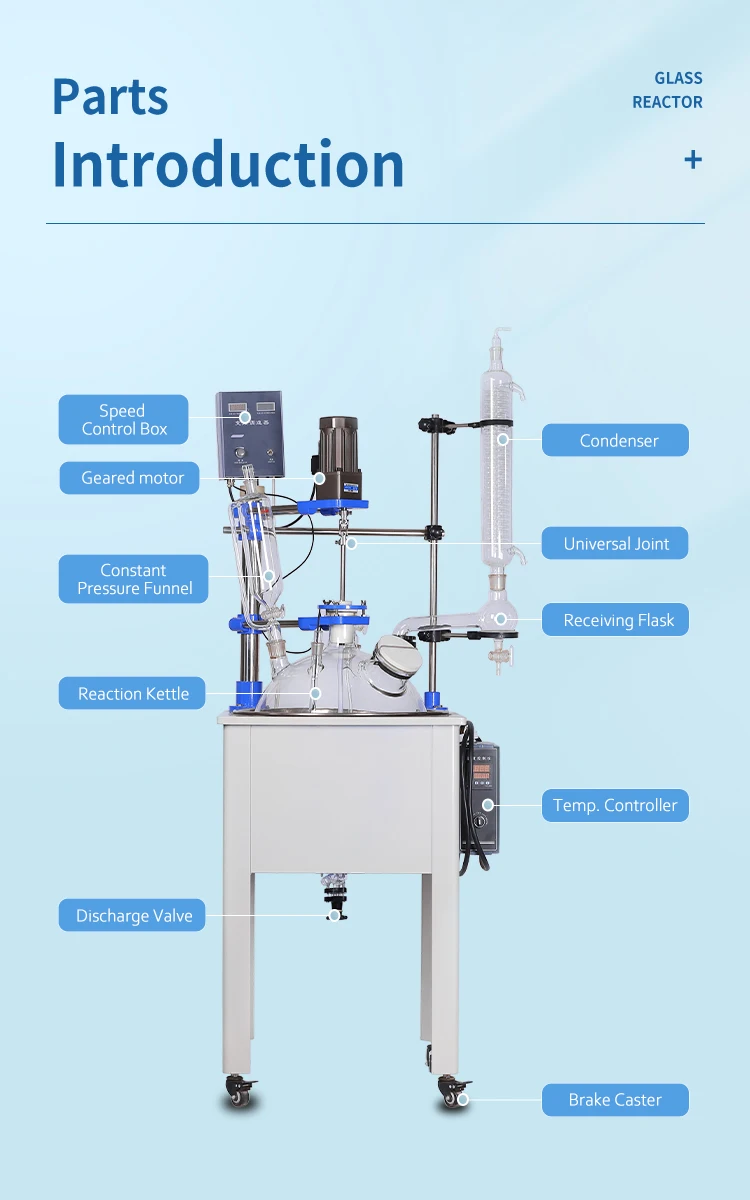

The working principle and application range of the Single Layer Glass Reactor: under the constant temperature condition, in the closed glass reactor, the stirring reaction can be carried out under normal pressure or negative pressure according to the use requirements, and the reaction solution can be refluxed. With distillation, the reaction is completed, the material can be discharged from the discharge port of the bottom of the kettle, and the operation is extremely convenient. It is an ideal pilot and production equipment for the synthesis of modern fine chemical plants, bio-pharmaceuticals, and new materials.

Single Layer Glass Reactor

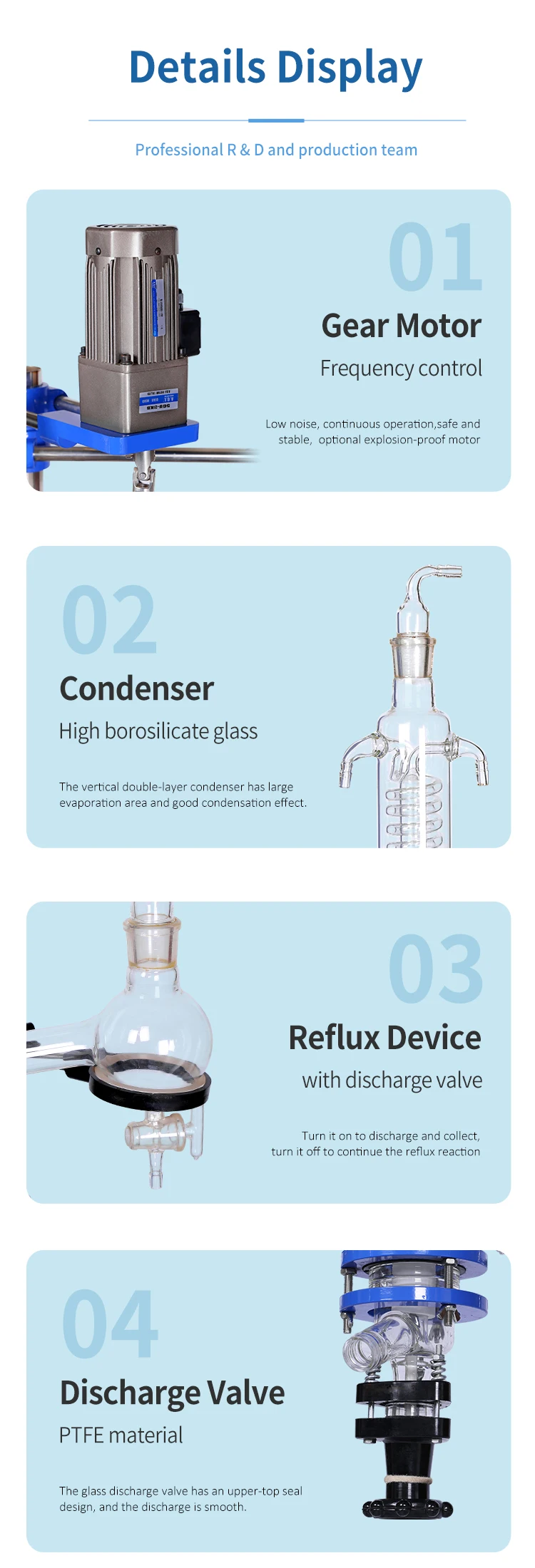

- All glassware is from First-class high-borosilicate glass that is heat/cold/corrosion-resistant, owns excellent chemical and physical performance.

- Overall Stainless steel (304)frame and screw with strong support and hardness.

- Its temperature using range is RT-250°C,Temperature can be customized to 350℃.

- Imported high torque reinforcement electrical machine, frequency conversion constant temperature stirring system, stable working state.

- Corrosion resistant discharge valve is without dead space design. solids / liquid material can be easily released from below.

MODEL | F-1L | F-2L | F-3L | F-5L | F-10L | F-20L | F-30L | F-50L | F-100L |

Voltage(V/Hz) | 220 50/60 | 380 50/60 | |||||||

Stirring Power (W) | 60 | 120 | 250 | ||||||

Stirring Speed (rpm) | 0-1000 | 60-600 | |||||||

Capacity(L) | 1 | 2 | 3 | 5 | 10 | 20 | 30 | 50 | 100 |

Heating Power (kW) | 0.5 | 0.8 | 1.2 | 1.5 | 3 | 4.5 | 6 | 9 | |

Heating Mantle Power(kW) | 0.53 | 0.65 | 0.73 | 1.1 | 2.1 | 3 | 3.8 | 5 | - |

Temperature Range(℃) | RT-250 (Heating in water & oil bath) RT-350 (Heating with heating mantle) | ||||||||

Motor Torque(g/cm) | 2000 | 2400 | 4800 | 1000 | 1200 | 1500 | 3000 | ||

Related Products for Single Layer Glass Chemical Reactor