Micrometer accuracy comparison

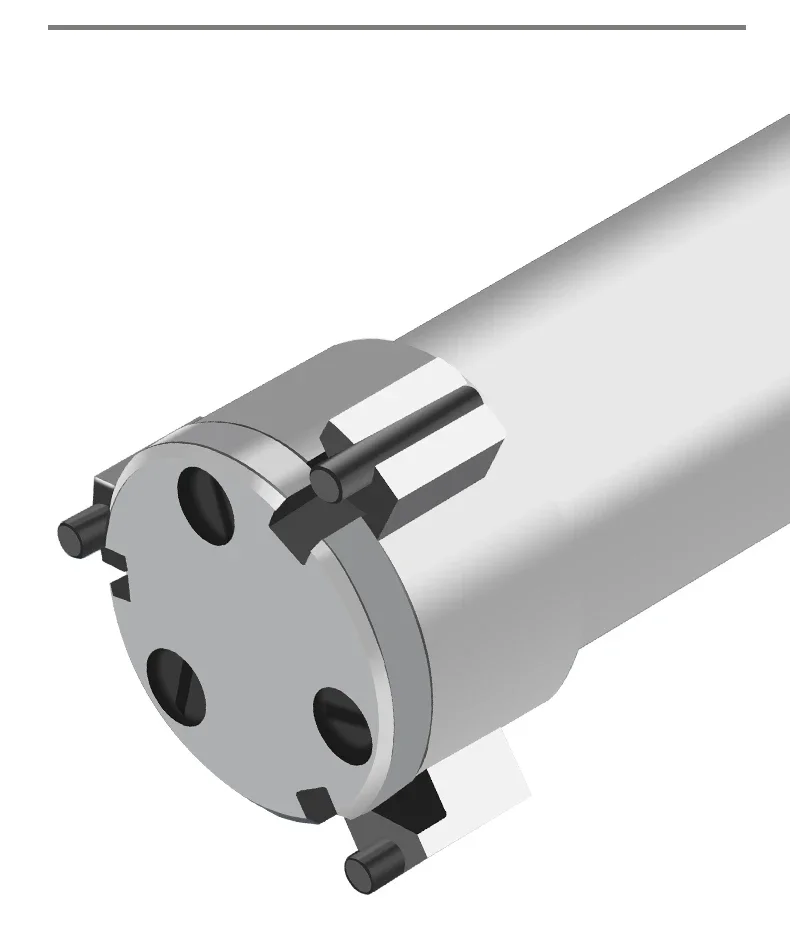

The technical difficulty of the three-jaw inner diameter micrometer lies in the gap between the measuring jaws. The larger the gap between the measuring jaws, the greater the measurement error.

~~~~~~~~~~~~

1. Full contact measurement on the measuring surface and 0-mark alignment

2. 3/1 measuring surface contact measurement deviation 0.04mm

Shanghai Hengliang brand, small gap between measuring jaws and small measurement error.

~~~~~~~~~~~

1. Full contact measurement on the measuring surface, 0 mark alignment

2. 3/1 measuring surface contact measurement deviation 0.005mm

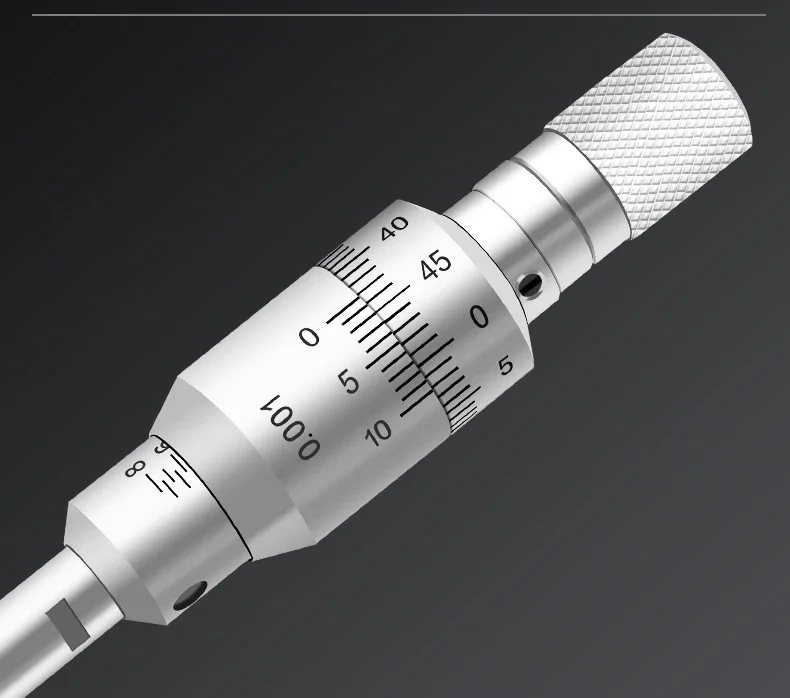

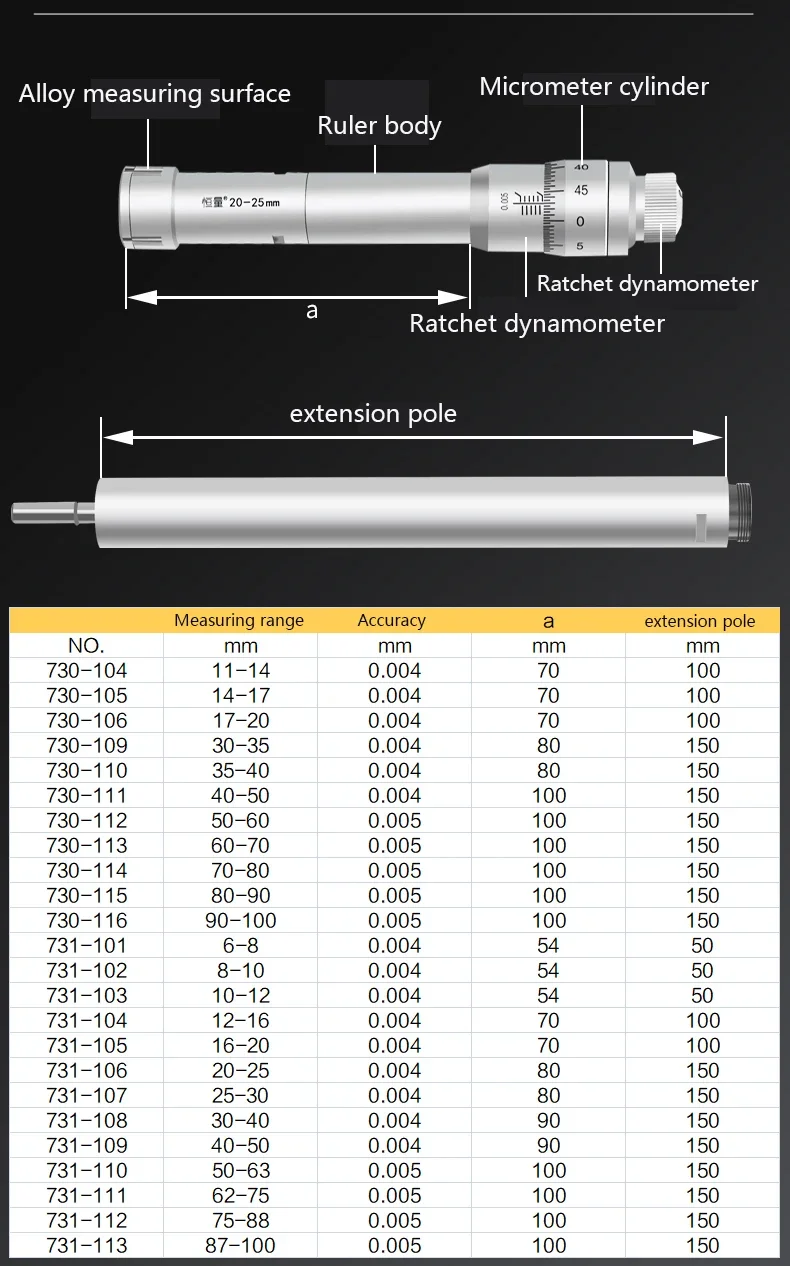

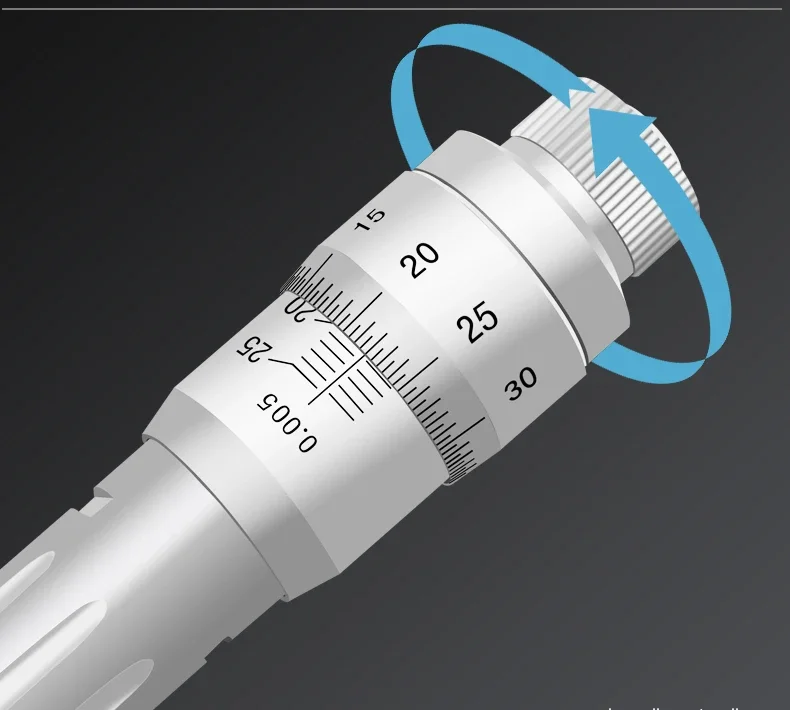

Differential roller flower design, comfortable to rotate. Ratchet force measuring device ensures accuracy.

The high-precision screw rod measures the precise inner hole, and the measuring surface is inlaid with carbide, which is wear-resistant and durable.

6-12 specifications are for parallax-free readings, and parallax-free readings are more accurate.