To All Our Dear Customers:

1. We promise all our products are from the original manufacturers directly;

2. We never sell the second-hand products in our store;

3. We provide 1-year warranty for all our products.

PUHUI T-8280 PCB Preheater IR Infrared Preheating Station Preheat Plate SMD Rework Station 0-450 Degree Celsius Solder Repair 110V/220V

1. This machine selects the infrared component to give off heat which independent exploration, adopts advanced PID intelligent temperature, controls temperature precisely.

2. T-8280 can achieve to heat PCB board and component which contains lead or not,especially for the BGA and SMD parts.

3. Use infrared heat, easy to cut through, heat proportion, dont have sirocco flow. Don't shift the small components on the PCB board,ensure the welding quality.

4. With 1500W heating system, heating area 280X270mm. Can use together with the handhold infrared welder T-835.

5. Easily operate, you can operate it through easy training.

6. T-8280 will satisfy soldering/unsoidering of phones, computers, notebooks, play station machines, etc.

Technical Parameter:

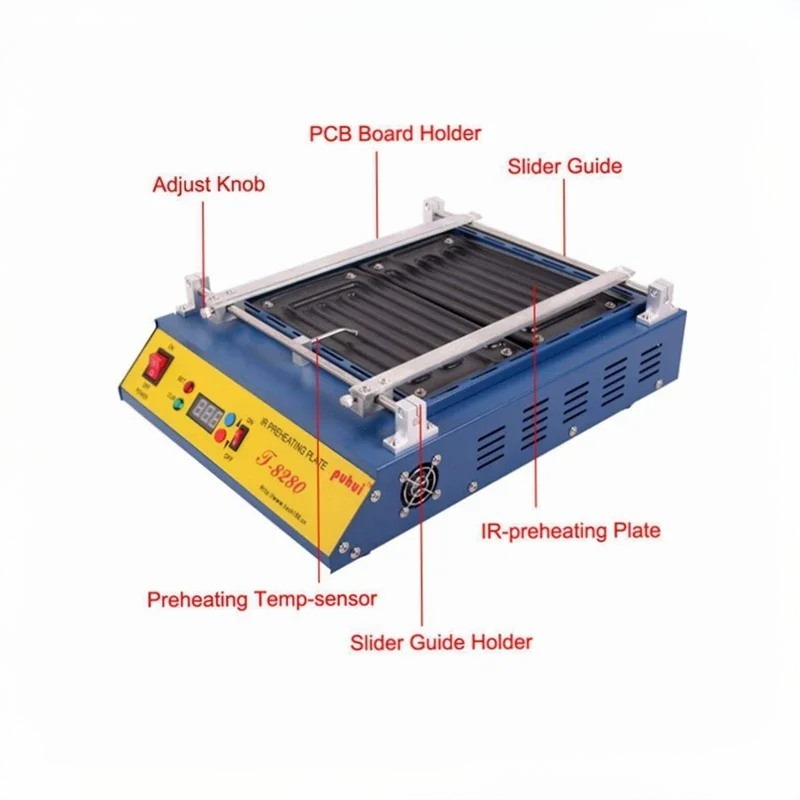

Main Components:

Main component function explanation:

Ope ration instructio ns:

1. Inspect the machine and then open it

Check the connection of the power line.

Turn on the power switch. Allow the T-8280 Power-On-Self-Test (POST) to complete. After this, Temperature set-points will display last value used.

The black switch on the front panel are used to control the infrared preheating plate; press the blue button (up),the red button(down), can adjust the infrared preheating plate temperature between 0 and 450. Press the button"ON", the infrared preheating plate starts to work, press"OFF", it stops working.

2. Operation of preheating PCB board

(1) The placement and adjustment of the PCB board:

According to the size of the PCB board, adjust the PCB board holder, then put the PCB board and fix the adjust knob.

According to the size of PCB board and welding technological requirement, press the blue button (up)and the red button (down), regulate the output temperature of preheating plate between 0 and 450.

(2) Preheating open and close:

Press the "ON" button,open the preheating plate about 3-5 minutes, make the temperature be the setting value then carry on the next step .

Finishing, press "OFF", the preheating plate stops working.

Attention: Don't close the power switch until the machine full cooling.

The preheating temperature set: If the PCB board contains lead, adjust the infrared preheating plate temperature to 100-120C; if not, adjust to 120-140 degrees. You can also set the preheating temperature according to the users experience and technology.

3. Machine installation and adjustment:

The preheating plate heating type includes: the total pressure flow-through heating way and the PID percentage adjustment way. You can adjust it according to the preheating allowance. Generally speaking, if the preheating temperature is lower than 250 degrees, selects the PID percentage adjustment method; and if the preheating temperature is higher than 250 degrees, use the total pressure flow-through heating way.

Adjustment method:

1. Press power-on.

2. Press choose 0 or 1, every press the status change one time,

C=0 is PID percentage adjustment, C=1 is switching control.

3. Press OK.

Cautions:

1. After finishing, don't turn off the power immediately; make sure the infrared preheating plate complete cooling.

2. Keep the ventilation free-flowing, the infrared preheating plate clean, use dehydrated alcohol clean it regularly

3. The high temperature operation, pay attention, avoid scalding.

4. If you don't use the machine for a long time, you had better pull off the power source plug.

Warranty:

The whole machine maintains for one year and the spare parts maintains for three months. Provides the immediate network online Q/A and the technical advisory work service.

Statement:

If there is any difference between users operating manual and actual product, according to the actual product.