VEVOR Dividing Head

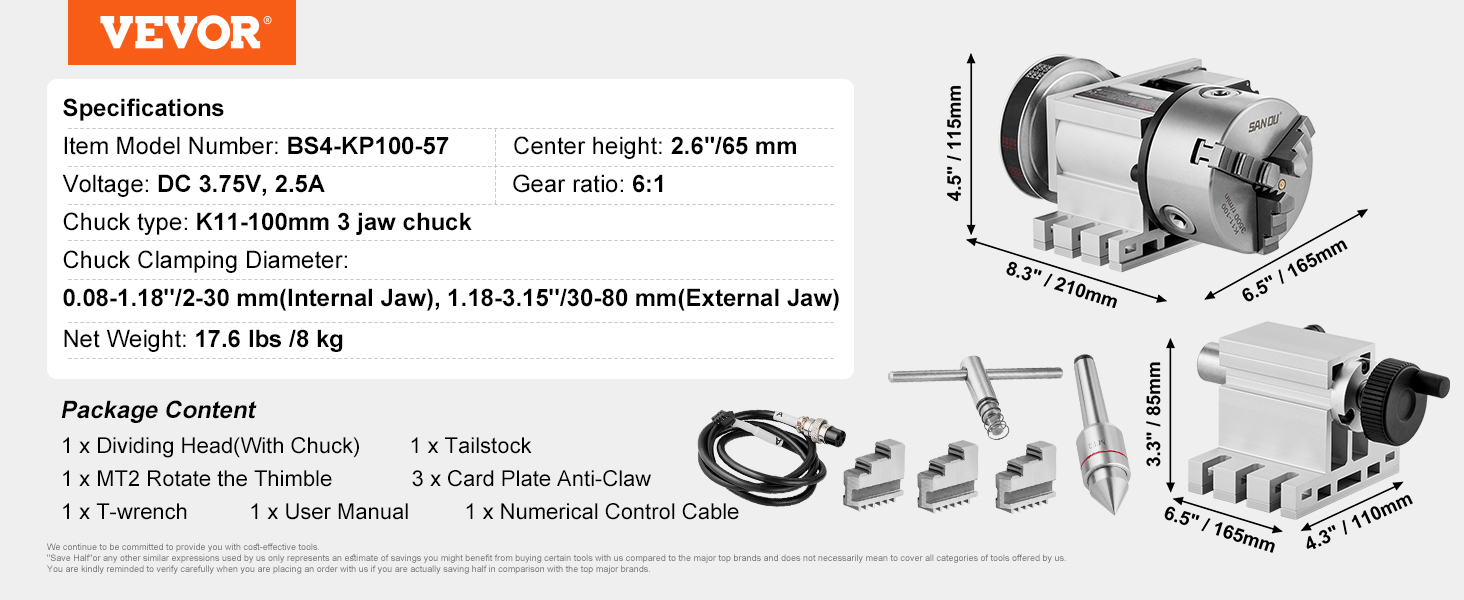

Our dividing head boasts the CNC Rotational Axis 4th Axis, a 6:1 reduction ratio, and a Nema23 2-phase stepper motor, offering unmatched precision across a wider range of indexing angles. The K11-100MM 3-jaw chuck enhances efficiency, making complex projects a breeze.

Equipped with a tailstock featuring an MT2 taper and a 0 to 1.6"/40mm travel range, our ividing head for milling machine ensures precise positioning for cutting, engraving, and other high-precision applications, enhancing your machining quality.

The hollow shaft design of our indexing dividing head offers an internal passage, making machining more flexible and precise. Processing multifaceted shapes becomes easier, unlocking endless possibilities for your machining tasks.

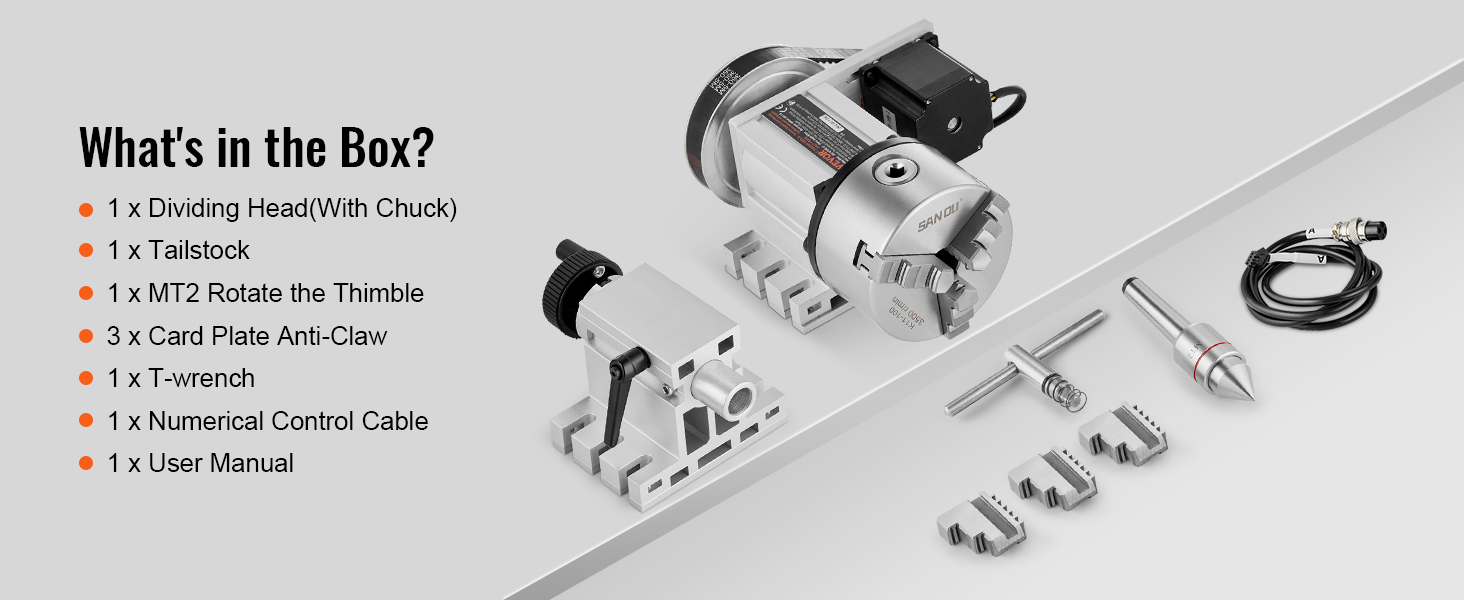

Our dividing head comes with 3 internal and 3 external jaws. Jaw changes are made incredibly simple with the included T-wrench, ensuring a firm grip for high-precision machining. Get ready for a seamless experience that keeps your work precise and efficient.

In addition to comprehensive accessories, we provide an extra signal cable. Simply connect this cable between the CNC dividing head and its control system. It ensures precise control over the rotation and other operations of the indexing head, elevating your machining accuracy to new heights.

Features & Details

- CNC Rotational Axis 4th Axis: Transform your CNC machine with the capability to carve from various angles and positions, effortlessly processing complex parts with curves or angular features. Featuring a K11-100mm 3-jaw chuck, this dividing head for milling machine boasts an inner through-hole diameter of 0.9"/22 mm and a center height of 2.6"/65 mm, enabling you to tackle intricate designs with ease and precision.

- Precision at its Best: With a 6:1 reduction ratio, our indexing dividing head lowers the motor's rotation speed, providing a broader range of indexing angles for your machining tasks. It assists in precisely positioning workpieces to achieve the desired angles, ultimately enhancing machining accuracy. Additionally, the reduction in speed ensures smoother motor operation, reducing machine vibrations and noise for a quieter and more refined workspace.

- Stepper Motor Excellence: Equipped with the Nema23 2-phase stepper motor, it measures a compact 2.2x2.2x2.2 inches (57x57x56 mm) and features four leads. This motor delivers precise positional control with a robust internal structure, ensuring high reliability and durability even during extended operation. Trust in its performance for the long haul.

- Rock-Solid Construction: The indexing head milling's exterior is crafted from robust 6061 aluminum alloy, treated with an anodized surface finish for exceptional wear and corrosion resistance, which ensures the protection of internal components from the harshest environmental conditions, providing longevity and reliability you can count on.

- 3-Jaw Chuck Mastery: Our K11-100MM 3-jaw chuck uniformly secures various types of workpieces with formidable clamping force. It comes complete with 3 internal and 3 external jaws, accommodating a maximum clamping diameter of 0.08 to 1.18'' (2 to 30mm) for internal jaws and 1.18 to 3.15'' (30 to 80mm) for external jaws. Changing jaws is a breeze, ensuring that your workpiece maintains precise positioning and orientation throughout the machining process.

VEVOR Dividing Head

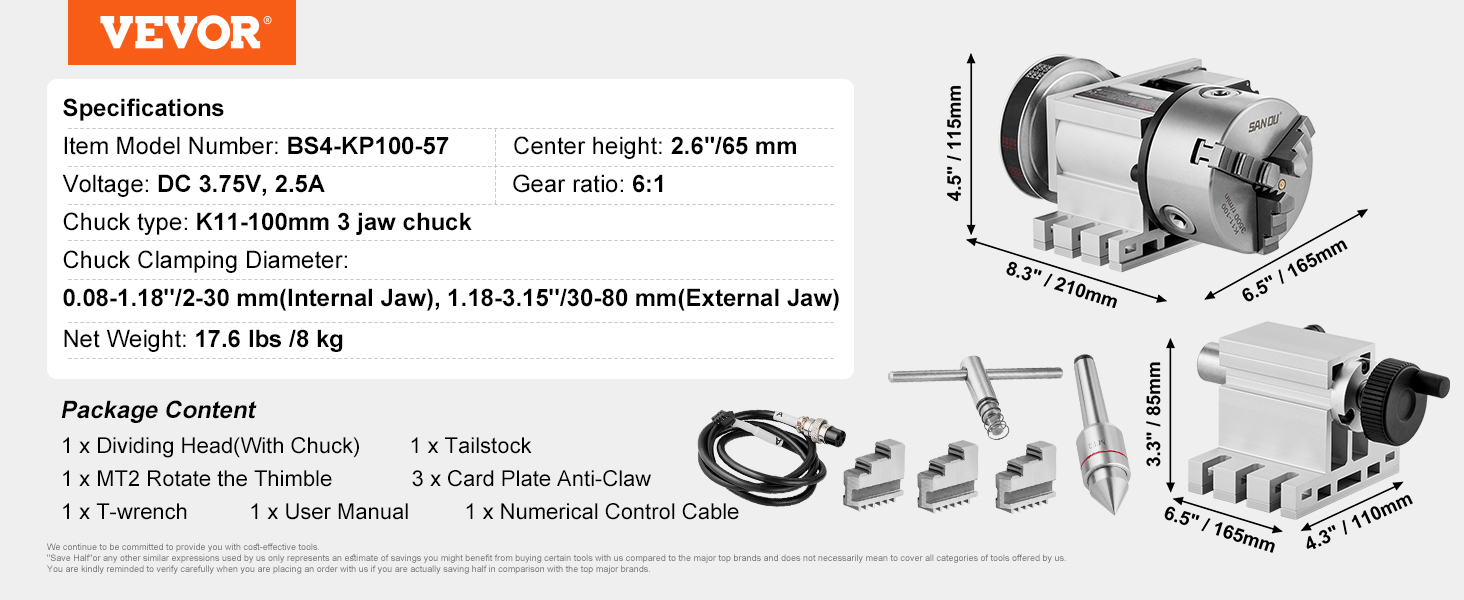

Our dividing head boasts the CNC Rotational Axis 4th Axis, a 6:1 reduction ratio, and a Nema23 2-phase stepper motor, offering unmatched precision across a wider range of indexing angles. The K11-100MM 3-jaw chuck enhances efficiency, making complex projects a breeze.

Equipped with a tailstock featuring an MT2 taper and a 0 to 1.6"/40mm travel range, our ividing head for milling machine ensures precise positioning for cutting, engraving, and other high-precision applications, enhancing your machining quality.

The hollow shaft design of our indexing dividing head offers an internal passage, making machining more flexible and precise. Processing multifaceted shapes becomes easier, unlocking endless possibilities for your machining tasks.

Our dividing head comes with 3 internal and 3 external jaws. Jaw changes are made incredibly simple with the included T-wrench, ensuring a firm grip for high-precision machining. Get ready for a seamless experience that keeps your work precise and efficient.

In addition to comprehensive accessories, we provide an extra signal cable. Simply connect this cable between the CNC dividing head and its control system. It ensures precise control over the rotation and other operations of the indexing head, elevating your machining accuracy to new heights.

Features & Details

- CNC Rotational Axis 4th Axis: Transform your CNC machine with the capability to carve from various angles and positions, effortlessly processing complex parts with curves or angular features. Featuring a K11-100mm 3-jaw chuck, this dividing head for milling machine boasts an inner through-hole diameter of 0.9"/22 mm and a center height of 2.6"/65 mm, enabling you to tackle intricate designs with ease and precision.

- Precision at its Best: With a 6:1 reduction ratio, our indexing dividing head lowers the motor's rotation speed, providing a broader range of indexing angles for your machining tasks. It assists in precisely positioning workpieces to achieve the desired angles, ultimately enhancing machining accuracy. Additionally, the reduction in speed ensures smoother motor operation, reducing machine vibrations and noise for a quieter and more refined workspace.

- Stepper Motor Excellence: Equipped with the Nema23 2-phase stepper motor, it measures a compact 2.2x2.2x2.2 inches (57x57x56 mm) and features four leads. This motor delivers precise positional control with a robust internal structure, ensuring high reliability and durability even during extended operation. Trust in its performance for the long haul.

- Rock-Solid Construction: The indexing head milling's exterior is crafted from robust 6061 aluminum alloy, treated with an anodized surface finish for exceptional wear and corrosion resistance, which ensures the protection of internal components from the harshest environmental conditions, providing longevity and reliability you can count on.

- 3-Jaw Chuck Mastery: Our K11-100MM 3-jaw chuck uniformly secures various types of workpieces with formidable clamping force. It comes complete with 3 internal and 3 external jaws, accommodating a maximum clamping diameter of 0.08 to 1.18'' (2 to 30mm) for internal jaws and 1.18 to 3.15'' (30 to 80mm) for external jaws. Changing jaws is a breeze, ensuring that your workpiece maintains precise positioning and orientation throughout the machining process.