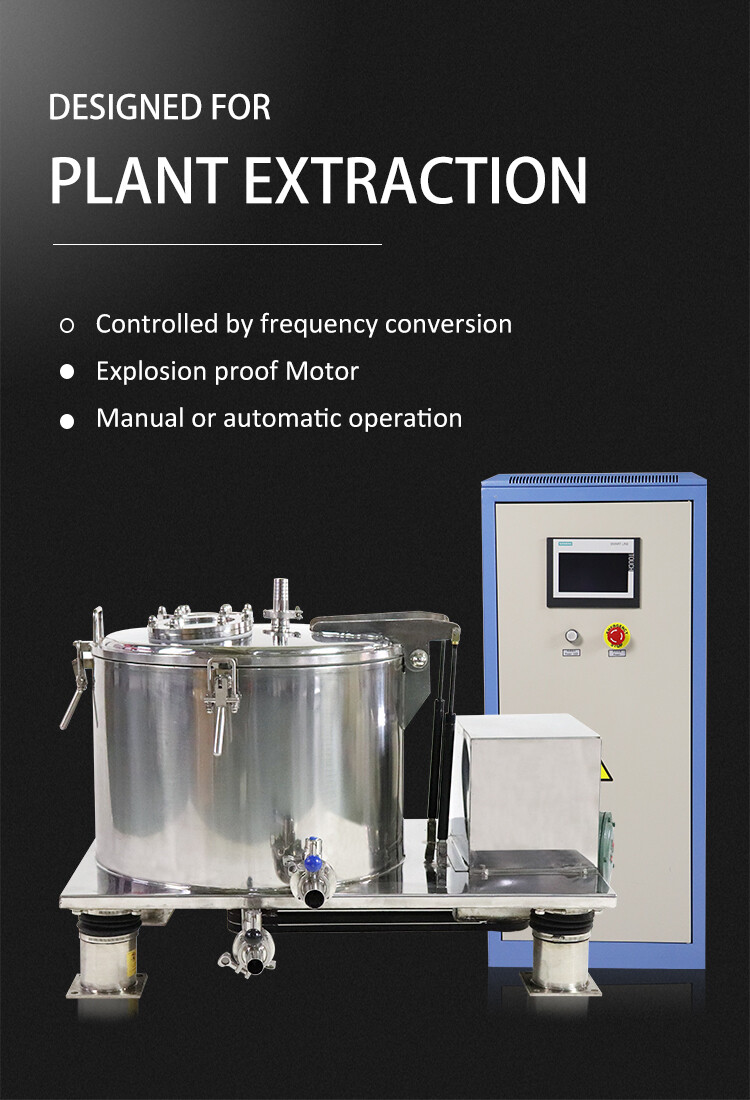

Lab Industrial 75L Centrifuge Machine Dehydrating Biomass Oil Extraction PLC US is top discharging, hermetic closure type equipment. The material is fed into the drum through the feeding pipe on the hermetic closure casing; under the action of the centrifuge force field, the liquid-phase passes through the filter medium and the discharged out of the machine, while the solid-phase material is retained inside the drum and, after the machine is stopped, the material is discharged from the top. The centrifuge has such features as smooth running, easy & convenient operation as well as conducting feeding, washing and dehydrating under the state of hermetic closure, etc

>>> Description

1. The top of the centrifuge usually has four ports, a glass visual window, an explosion-proof lamp, a feed port, a liquid inlet, also can be customized according to the specific needs of customers.

2. All the parts contact with material is made by SS304L stainless which can fully fit the food grade processing requirement.

3. The inner bowl can be used the filter bag with 200-600 mesh and the material of the filter bag can be customize by client selection. After separation, the solid will collect on the bag , then stop machine , remove the filter bag.

Contrasting with other filter machinery, this filter centrifuge have good capacity with high paste holding by the filter bag thus each coconut oil processing plant need this filter centrifuge indeed.

4. The controller part uses Siemens imported touch screen, Honeywell frequency converter from American, Schneider electrical components.

5. The main bearings of centrifuge are all NSK. imported from Japan.

>>> Application

This type filter centrifuge are widely used in food, chemical, pharmaceutical industry. For separating some crystal from liquid, Salt, Calcium carbonate,Copper sulphate, etc.

And it is also good at extracting plant oil.

>>> Principle of use

Oil Separator Low Speed CentrifugeThe motor drives the basket to rotate at high speed through the belt, and under the control of pre-written program, the material to be separated is fed into the basket through the feed system. After the material is filtered through the filtration medium (filter cloth/screen) under the action of centrifugal force, the liquid phase discharges out of the centrifuge through the liquid pipeline, and the solid phase is retained in the basket. A material detection device is used to detected material filling position in real-time manner, and when the solid cake deposited in the basket reaches the specified holding capacity of the centrifuge, feeding stops. Then wash and dry the solid cake. After the solid cake meets requirements for knock-out, the centrifuge reduces to the scraping rate, under the hydraulic (pneumatic) control, the scraper device removes the solid cake, and then the cake id discharged at bottom outlet of the centrifuge.

- Payment should be completed within 4 (Four) days of auction closing. Or unpaid dispute will be filed for closing auction.

- We will leave a positive feedback immediately after payment is received. We appreciate a positive feedback as much as you do. If for some reason there is any issue with the purchase, please contact us prior to leaving feedback, we will be glad to work together and provide a satisfying solution.

- We only ship the item to the eBay Verified address that is sent to us at the time of checkout, most shipment will be shipped within 1-5 business day. Please verify the correct shipping address in your eBay account before making your payment. Shipping time during holidays may take longer than normal.

- Any brokerage, customs, and duty fees associated with international shipments are the customer's responsibility and are not included in our shipping charges.

- If you are located outside of the continental 48 United States, please email us in advance to see if the specific item ships to your location. These orders are generally shipped within 1-5 days after payment is received.

- Please be patient as they are often subject to additional inspection upon delivery.

- All of our items are backed with a 30-day return policy. We ensure all our items are new and in excellent condition prior to shipping. In case you receive the item that is not to the standards above, please contact us via e-Bay messages. All returns must be in new original condition as received and should be shipped with delivery confirmation

- Please note that all returns must be pre-approved by us. Unauthorized returns will not be accepted. If you need to return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation.

- We ONLY accept returns with original package. Please make sure that item has NO man-made sabotage. Used items will not be accepted for return.

- We are a comprehensive company specializing in the research and development, production and sales of lab related equipment. Company tenet: Respect reputation and contract, provide high-quality and low-cost equipment for serve scientific research.

- We believe that it is our vision and mission to provide innovative products with best service and competitive price to satisfy you. Our goal is to make sure that you can find exactly what you are looking for and make it easy for you to place your orders.

- Email Customer Support:

- 9:00am-2:00am PST Sunday-Friday

- All emails will be responded to within 12-24 hours

| Brand | ZZKD |

|---|---|

| MPN | Does Not Apply |

| Features | Digital Display |

| Speed Type | High Speed Centrifuge |

| Intended Use/Discipline | Biological Laboratory, Medical Laboratory, Microbiological Laboratory, Physical Laboratory, Physical Medicine & Rehabilitation |

| Model | PPTD-50 |

| Country/Region of Manufacture | China |

| Drum Diameter | 600(mm) |

| Jacket capacity | 43L |

| Max. Load | 60KG |

| Rotating Speed | 1500(r/min) |

| Separation Factor | 755 (r/g) |

| Motor | 3(KW) |

| Frequency Converter | 4(KW) |

| Machine Weight | 750KG |

| Voltage | 220V |

| Certification | ISO9001 |

| Drum capacity | 85L |