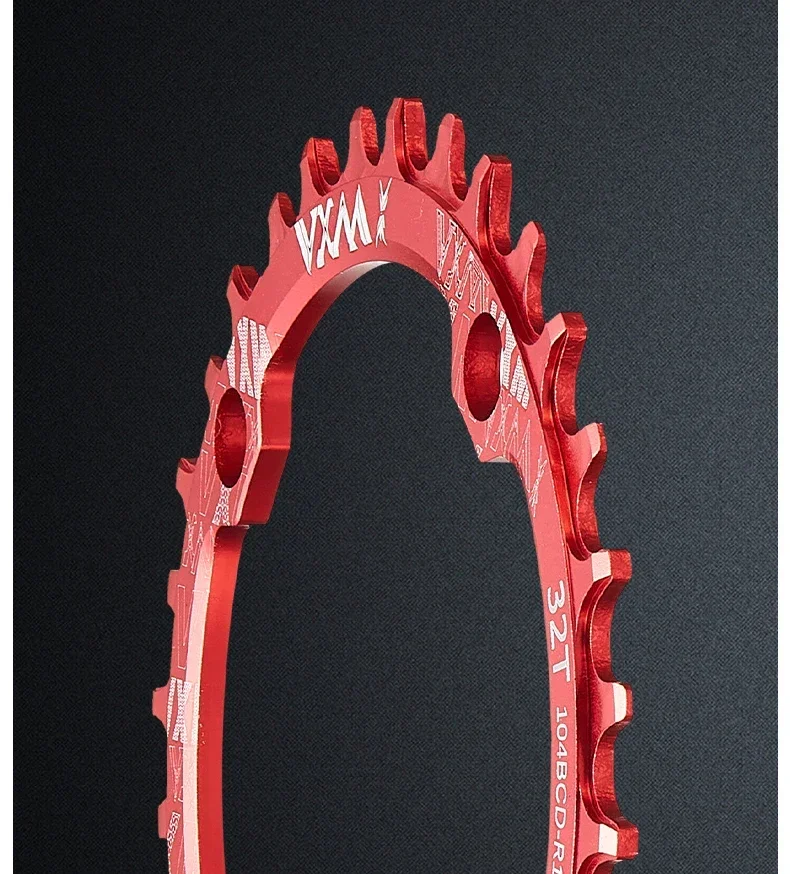

Aluminum alloy forging anodizing

High precision positive and negative tooth positioning

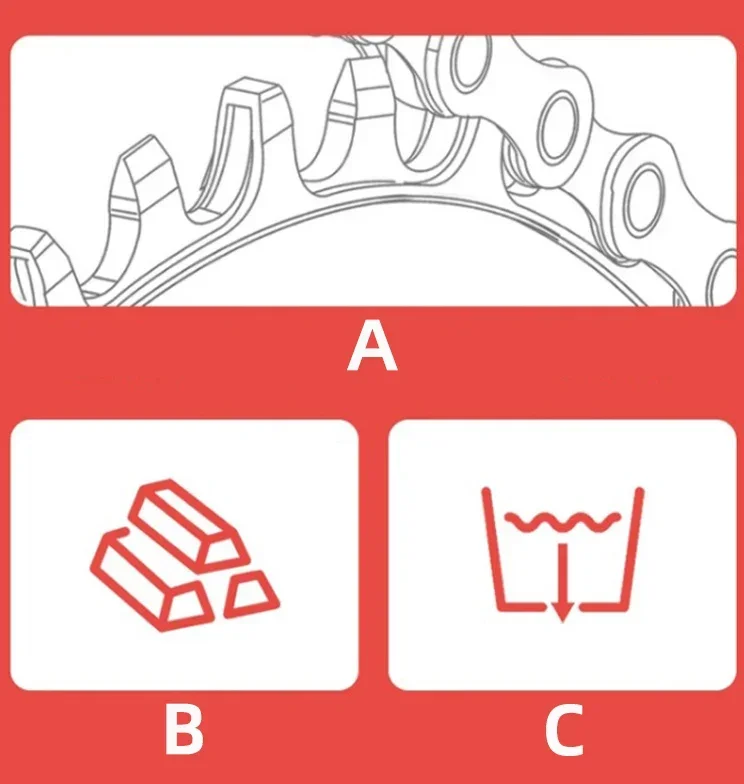

A:Arc cutting angle, strong engagement force between positive and negative teeth positioning slots, reducing vehicle load, ensuring smooth and powerful operation without chain breakage during cycling

B:All aluminum alloy forging surface with strong anodizing, impact resistance, and obvious rust prevention effect

C:The inclined mouth of the mud discharge prevents sediment accumulation, and the teeth run smoothly

Strong biting force of positive and negative teeth positioning slots

Anodic oxidation of aluminum alloy forging surface

All aluminum alloy has strong forging strength, strong impact resistance, uniform stress, smooth cycling, and surface anodizing, effectively protecting the aluminum alloy body and preventing surface rust and oxidation

All CNC integrated molding

Lightweight aluminum alloy fully CNC process, with strong rigidity and high hardness; Stable structure without deformation due to intense stepping, greatly improving durability

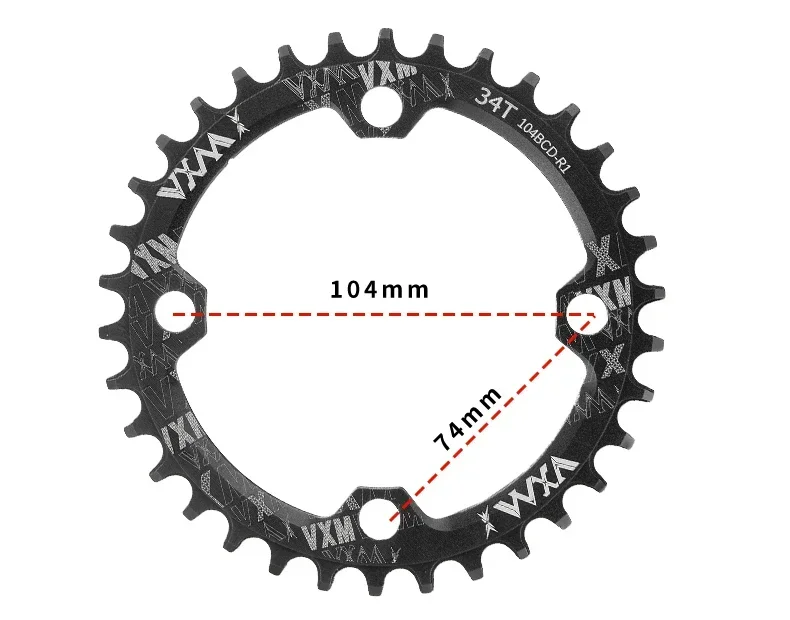

Lightweight 104BCD disc shape

The single disk system eliminates the need to install front dial, left finger dial, medium to large disk, and some line pipes to reduce weight and meet the needs of different scenarios

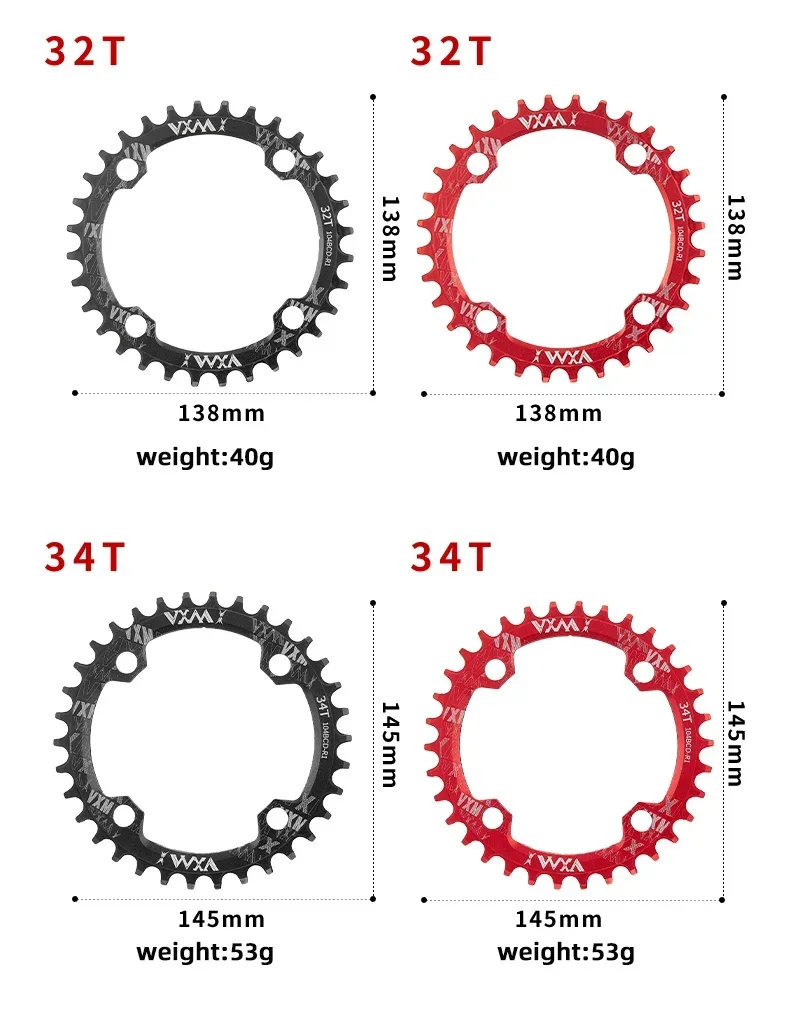

Product parameters

Product Name: Positive and Negative Toothed Disc

Material: CNC aluminum alloy Process: integrated turning milling anodizing

Specification: 104BCD

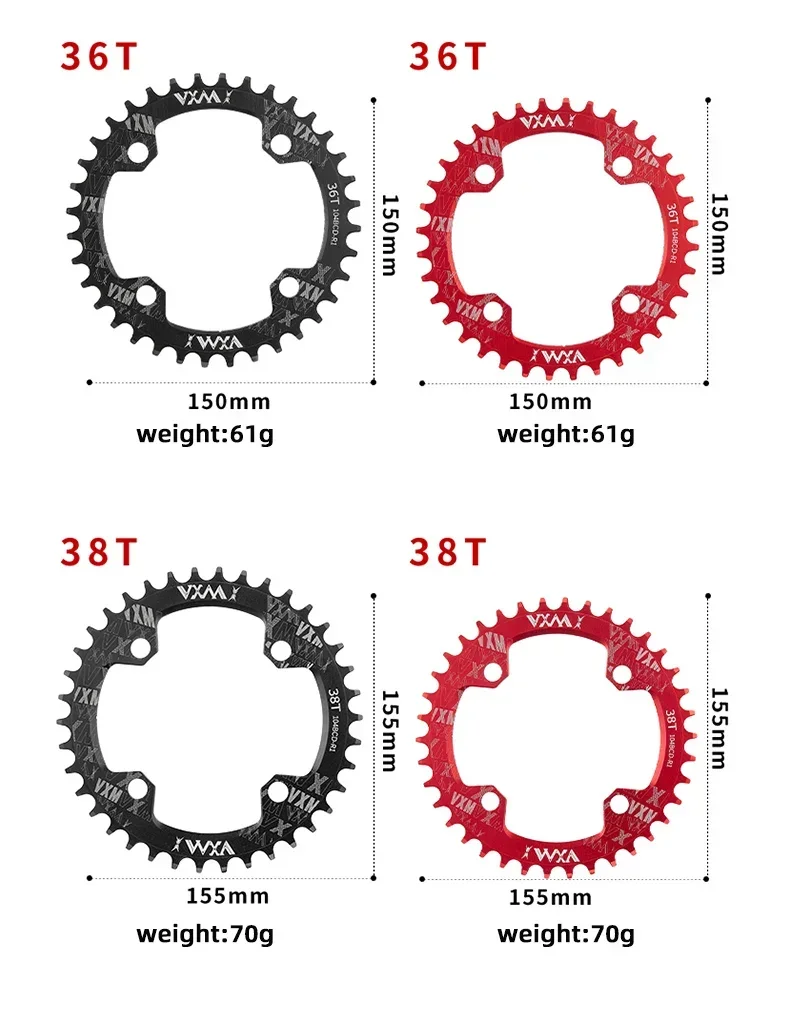

Color: black, red

Packaging: Color box

Specification: 32/34/36/38T

Photo Show

Screws Specification:

Color: Red,Yellow,Green,Blue,Silver,Black,steel

Size: 4.9mm single disc, 6.4mm double disc

Material: aluminum alloy, tool steel

Weight: About 30g

Size: disc screw: 12 * 9.6 * 4.9mm/12 * 9.6 * 6.4mm

Disc Nail Tool: 92 * 1.5mm